For decades, the mark of a “luxury” hotel was a massive, bustling kitchen where everything from tomato puree to complex dal bases was prepared from scratch. But in 2025, the narrative has shifted. Walk into the kitchens of India’s leading 5-star chains, and you’ll find a new secret to their success: Professional Ready-to-Eat (RTE) and Ready-to-Cook (RTC) partnerships.

The move isn’t about cutting corners; it’s about precision, sustainability, and operational excellence. Here is why the industry’s biggest players are moving away from manual “scratch” prep and partnering with innovators like Transgreen.

1. Solving the “Labor vs. Quality” Paradox

The hospitality industry is facing a dual challenge: a shortage of highly skilled chefs and a rising demand for consistent taste.

- The Traditional Problem: If a sous-chef at a Pune property leaves, the taste of the Dal Makhani shouldn’t change—but often, it does.

- The RTE Solution: By using standardized bases and meals from suppliers like Transgreen, hotels ensure that their signature flavors remain identical across every property, from Delhi to Bangalore. This allows executive chefs to focus on plating and guest experience rather than supervising the consistency of a bulk gravy.

2. Slashing Operational Overhead

The “true cost” of in-house prep includes more than just ingredients. It includes hours of labor, massive electricity bills for cold storage, and the high cost of kitchen space.

- Transgreen’s Edge: With a state-of-the-art 8-acre facility in Gujarat, Transgreen utilizes advanced IQF (Individually Quick Frozen) and Blast Freezing technologies.

- The Benefit: Hotels can reduce their “mise-en-place” (prep) time by up to 70%. Instead of a 4-hour slow-cook, a gourmet base is ready in minutes, allowing for faster table turnover and smaller, more efficient kitchen footprints.

3. Sustainability: The Farm-to-Fork Mandate

Modern guests—especially Gen Z and Millennial travelers—demand to know where their food comes from. High-end hotels are now held to strict ESG (Environmental, Social, and Governance) standards.

- Ethical Sourcing: Transgreen stands out in the HoReCa sector for its “Farm-to-Factory-to-Fork” approach. They prioritize ethically sourced ingredients and sustainable agriculture.

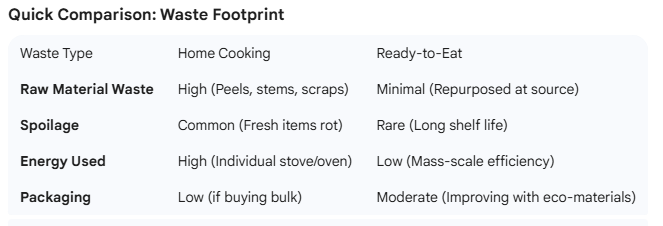

- Zero Waste: When a hotel prepares 50kg of gravy and only sells 30kg, the rest is waste. Professional RTE products are portion-controlled and shelf-stable (or frozen with precision), meaning hotels only “fire” what they sell.

4. Safety and Compliance at Scale

Maintaining HACCP and FSSAI standards in a high-volume hotel kitchen is a constant battle against human error.

“Professional suppliers like Transgreen bring industrial-grade safety to the boutique kitchen. Their facilities are designed to meet global export standards, ensuring that every pouch is free from contaminants and preservatives.”

The Future of the Professional Kitchen

The transition to professional suppliers isn’t just a trend; it’s a structural change in how hospitality works. Brands like Transgreen are no longer just “vendors”—they are innovation partners that help hotels scale profitably while keeping the “soul” of their recipes intact.

In 2025, the best chefs aren’t the ones doing the most peeling; they are the ones using the best technology to deliver an unforgettable meal.